Electrical Odd and Ends

These are electrical-related odds and ends (posts from the GSR forum) that I wanted to keep for future reference.

Back to BikeCliff's website.

On this page:

Stock Bulbs

For my GS850GT, and most other GS bikes, the stock bulbs are as follows:

Headlamp (recommended):

Sylvania Silverstar H4ST - a high performance halogen headlamp, maximum

55w/65w with 7" round headlight. Can be found at just about any

auto store. |

Stop/Brake lamp: Stanley 1034 - 12v, 23w/8w

Turn Signal lamp: Stanley 1073 - 12v, 23w

Gear Indicator Bulbs: 12v 35mA, 5mm dia. available from Parts Express.

|

Licence Plate lamp: Stanley 67 - The full Stanley part number is A41B 67, 12v/8w.

Instrument lamp:

#194 or #158 (miniture w/wedge base) is close enough. (OEM 12v/3.4w is hard to find.) |

| In many cases, a generic 2-prong FL-522 or 552 flasher can be used in place of the stock turn signal flasher. Note that this will disable the auto-canceling feature of your turn signals. |

Tridon, Bussman, and others make 522 and 552 flashers. Tridon, Bussman, and others make 522 and 552 flashers. |

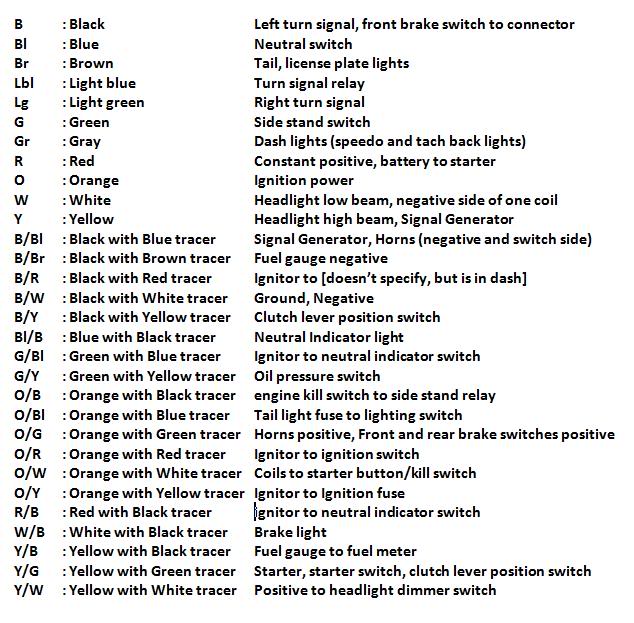

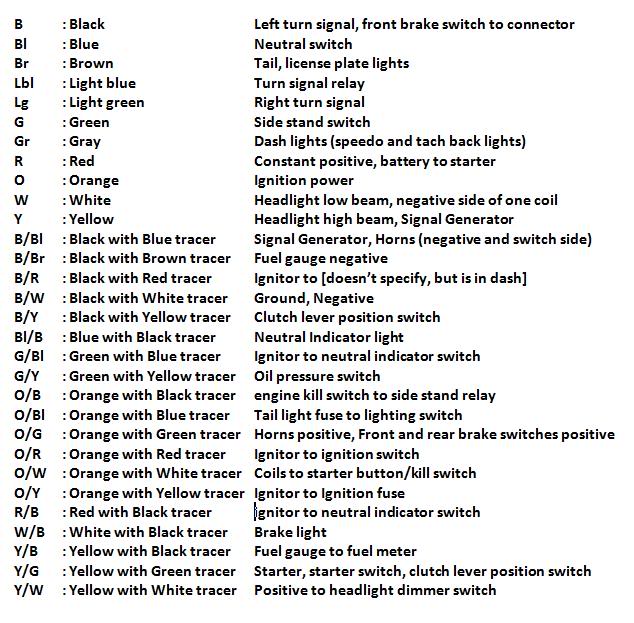

Wiring Color Chart/Usage

Spark Plug Cap Replacements

thanks to Ms. SqDancerLynn1

For replacing the stock caps use 2 each - NGK XB05F and VB05F.

Cut

off a small slice (1/4 inch) of the end of the plug wire and screw in the

new plug caps. This makes a good connection with fresh

(uncorroded) wire.

The part numbers above work on my 1980 GS850G. For a full explanation of NGK plug cap part numbers see: http://www.sudco.com/spark.html

A source for "vintage" connector parts: http://www.vintageconnections.com/

Z1Enterprises

also has a good selection of electrical connetors, terminals, wire,

etc. Look in the electrical section under your bike model.

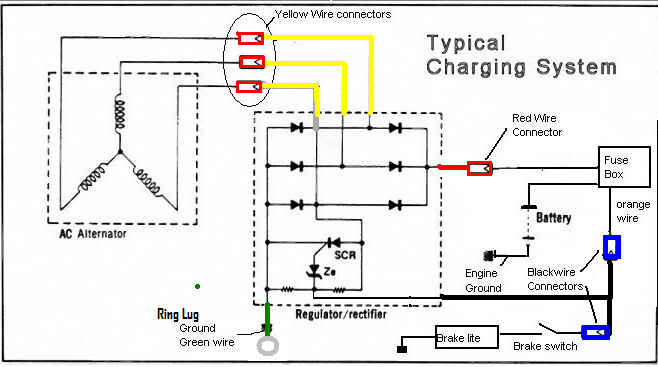

Compatible Stators and R/R Units:

CLICK HERE for a list of compatible stators and FET regulator/rectifiers for the GS850 and other bikes.

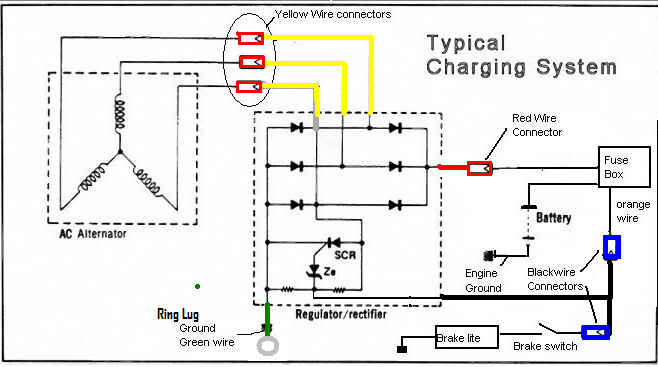

A wiring diagram for 6-wire Honda r/r units:

More on the Stator Papers

Mr. posplayer has tweaked the first couple of pages of the Stator Papers fault finding chart to make the procedure more detailed and more thorough.

CLICK HERE to download the PDF file.

From Mr. posplayr:

Here is what I tried to do in

modifying it [Phase A of the Stator Papers Fault Finding Chart]:

-

The first step is to insure

that the is some charging going on when you raise the idle up to

2500 RPM the battery voltage should increase. If it doesn't then you

should still test and clean the connections in Step 2 and 3 but if

the stator is bad, then you will get through all of Phase A and

still have low output.

Battery Charging

Here is a very thorough article about how to initialize and charge a motorcycle battery:

http://bmwmotorcycletech.info/newbattery.htm

Regulator/Rectifier Diode Test

I performed a diode test on a good spare 6 wire Honda Shindengen r/r unit. These are my results.

Here's what I get on my diode setting:

1) Starting with the (+) lead on the sense wire:

All (-) connections to red output, green ground, and yellow inputs read "+OL".

2) Reversing the leads, putting the (-) lead on the sense wire:

The (+) connection reads:

Red output = +OL

Green ground = ~ 1.5v

All yellow inputs = +OL

3) With the (-) lead on the red output:

The (+) connection reads:

All yellow inputs ~0.54v

Green ground ~0.99v

Black sense +OL

Reversing the above reads +OL on all combinations.

4) With the (+) lead on green (ground) wire and (-) lead on the yellow wires should read ~.54

Should real "+OL" when connections are reversed.

5) Probing between all of the yellow inputs in any combination reads +OL.

Note that the step 3) "all yellow" inputs are the same as the yellow,

blue/white, green/white (or red/white) wires connecting from the stator.

Also note that in step #3, when testing between the red output and

"yellow" input wires, the "~0.54v" readings can vary depending on the

r/r model and the multimeter. As long as the readings are consistant,

anything between ~0.4v and ~1.0v should indicate a good circuit. If one

of the three readings is significantly different from the other two

(i.e. two read .4 and the other one reads .7), the the r/r unit would

be suspect.

Connections to the sense lead on a Honda r/r are irrelevant for diode

tests and are included for information only. Steps #3 and #4 are the

critical tests. This same test is valid for 5-wire r/r units, just

disregard the "sense" wire information.

More On Coil Relay Modification

Here are a couple more PDF files by Mr. Matchless that help explain the coil relay mod and other uses for relays.

Relay Modification For Older Bikes

Ignition Coil Relay

My Coil Relay Mod Story - by BassCliff

Under

my tank there are two orange/white wires coming out of the wiring

harness, one going to each coil. I cut both of them. The two o/w

wires that go back into the harness go up to the kill switch. The

other side of the o/w wires go to the two coils. On both sides I

stripped the wires a little, wrapped them together, tinned them with

solder, and crimped them both into a spade connector. Now both of

the wires going to the coils are crimped into one connector. Also,

the two o/w wires coming out of the harness are crimped into one

connector. I poured over the wiring diagram for my bike to make sure

it would work this way. It did.

[The

following paragraph is somewhat speculative. I'd have to check a

wiring diagram to be sure.] Some coil relay mod diagrams show that

one of the o/w wires going back into the loom is left unconnected.

While this doesn't affect the operation of the relay mod on the

coils, it would seem to disable the kill switch. My kill switch still

works.

Then

I ran 2 wires (both red in my case, you may want to use different

colors) all the way back to the relay next to my battery box. I had

to be careful to label the wires correctly so that I know which one

goes to the coils and which one goes back into the wiring harness.

I

took a Sharpie and wrote on the plastic covers of the spade

connectors (you've seen them on my r/r replacement guide and such).

I came up with a little mnemonic to remember what goes where.

There

are 4 connections on the standard relay; 30, 85, 86, 87. The power

from the battery gets connected to #30. Then, like the car Mazda

made years ago - Mazda GLC, the Great Little Car - I think "G-L-C"

for the rest of the connections. G for ground. L for loom (another

name for the wiring harness), and C for coils. (+)=30, Ground=85,

Loom=86, Coils=87.

In

this manner I used my Sharpie to write "+", "G",

"L", "C", on the connections at the relay. The

connections at the relay are all female spade connectors since the

relay has the males. If I ever want to take the relay out of the

circuit I can...

-

Pull

the fuse on the hot wire to the battery.

-

Disconnect

the "C" and "L" connections from the relay.

-

Use

my short jumper, with male connectors at each end, to reconnect (C

and L) the coil wires back into the harness.

My

clutch interlock was not affected at all. I still have to pull the

clutch in to start my bike even if it is in neutral.

If

everything else is well-maintained in your engine, then even if you

have some loss at the coils, there is enough spark to start

combustion. But a good, fat spark gives you the most efficient burn.

It's usually when the voltage falls below 10v that you really start

having problems, especially if there is anything else wrong with your

motor. These engines are so well designed that they can take a LOT

of abuse before they quit running.

General Spark Plug Information

Reading spark plugs, caps, gaps, etc:

http://www.totalmotorcycle.com/maintenance/sparkplugs.htm

Also see: Spark Plugs, How to Read

GS850 Color Wiring Diagram Erata

Originally Posted by Mr. Steve

The wiring diagram in many Clymer manuals is incorrect.

I have seen problems with many different versions of these Clymer diagrams, I have not checked any of the Haynes pictures.

The problem is in the power wire. There is a red wire that goes from the battery to the fuse panel, 4th and 5th fuses. Good.

From the right side of the 4th fuse it goes to the ignition switch. Good.

Looking

at the connections in the ignition switch, it then comes out the gray

wire, which goes halfway across the page, then up and branches out to

feed the lights. NOT GOOD.

The gray wire and the orange wire are

switched at the ignition key. It is the orange wire that then goes back

to feed the top three fuses.

If

you switch the positions of the orange and gray wires, the rest of the

diagram is OK. Also note that there were features added that do

not show up in this diagram, like the sidestand switch in the '82 and

newer models.

(Here is a link to the correct color diagram.)

Simplify The Wiring Diagram

Originally Posted by Mr. Steve

A quick tutorial on how to view the diagram to make it look easier:

Find

the battery. There is a line that goes from there to the fuse panel.

Follow the path through the main fuse to the ignition key, then back to

the fuse panel, where that power wire feeds three other fuses. The top

fuse only powers the head light, tail light and meter lights, so if you

have problems with lights, look at the top fuse. The second fuse only

powers signal devices. These devices are the turn signals, brake light

and horns. The third fuse only powers the igniton. You have now broken

up the diagram into three considerably smaller sections, making it much

easier to track what is going on.

Diagnosing Slow Cranking

Originally posted by Mr. Steve

To

help diagnose this problem, you will need a voltmeter and probably a

helper. It does not matter if it is analog or digital. Clip the black

wire of the meter to the negative terminal of the battery. Touch the

red lead to the positive terminal (make sure it's the terminal, not any

of the wires that might be connected), note the voltage. Press the

starter button (have your helper pull the clutch and push the button

while you handle the meter), note the voltage. If it dropped below 10

volts, you need a new battery. Yeah, it may be "charged", but it does

not have enough capacity left to handle the starter. You can also prove

this by using jumper cables to connect your bike to your car (with the

engine not running) and cranking again. If the starter spins now, you

know it's your battery. If the voltage did not drop that much, continue.

Now

touch the battery terminal on the starter solenoid (again, the

terminal, not the wires), note the voltage when you press the starter,

it should be the same as the battery terminal voltage. A drop here

would indicate bad connections. Clean them and try again. Now touch the

red meter lead to the bolt that holds the wire to the starter, do the

same tests. Again, you are testing for bad conections.

It is

possible, though, that the starter itself is dragging a bit. You will

have to remove the starter from the bike and connect jumper cables to

it and a good battery to test. Be careful when you make that last

connection, though, the starter has quite a bit of torque and will try

to jump out of your hands.

Also keep in mind that getting power

to the starter is only half the battle. You also need to have reliable

ground connections, so make sure the starter is securely bolted to the

engine, and that you have a good connection from the engine block to

the battery. Most bikes will have a wire (cable) from the engine to the

chassis and another from the chassis to the battery, so make sure all

the connections are good.

Igniter/Signal Generator/Coil Test

Originally posted by Mr. Billy Ricks

This is for an '85 700 but you can probably use the same tests for your bike.

Here's

how to check the ignitor. Remove spark plugs 1 & 2 and ground them

to the motor so they will fire when they get power. With the ignitor

facing you, the plug on the right side of the ignitor is where the

signal generator plug fits. The two terminals on the right side of that

portion of the ignitor will be pin 1 at the front and pin 2 at the

back. The two left pins will be pin 3 in front and pin 4 at the back.

Turn the ignition switch on. With a multitester set a the X1 ohm range

put the + probe on pin 2 and the - probe on pin 1. Plug number 1 should

fire. Next put the + probe on pin 4 and the - probe on pin 3. Plug

number 2 should fire. If this happens the ignitor is good and the

signal generators are suspect.

As for testing the pickups,

signal generators, measure the resistance between the two wires on each

pickup. You should get somewhere around 130-200 ohms. If the resistance

is infinity or less than spec they are shot.

To test the coils

put one probe of the multitester on each of the terminals on the

primary side of the coil. You should get 3-5 ohms. Check the secondary

windings by placing one probe into each of the plug wires coming from

one coil. Those would be 2 & 3 from one coil and 1 & 4 for the

other. You should get 30-50,000 ohms for stock coils and 15-20,000 for

aftermarket.

Here is another procedure to test the igniter by Mr. almarconi

Remove the spark plugs of #3 and #4 cylinders, fit them into the plug caps, and place them on the cylinder head.

Remove the frame cover on the right side and disconnect the lead wire from the signal generator.

Connect (+) lead of voltmeter [set to ohms] with blue lead wire on the

ignitor side, connect the (-) lead on the voltmeter with the green lead

wire.

The moment the test leads are connected, the electrode of spark plug of #4 fires. The moment the test leads are disconnected, the electrode of spark plug of #3 fires.

Stator Rewinding

Using the stator rewinding guide in the Garage Section of The GS Resources website, Mr. Nerobro documents his stator rewinding experience in this thread on the GSR Forum.

Lighting Upgrades

Here

are a couple of links with guides to help you turn your single-filiment

turn signals into dual-filiment running light/blinker combiniations.

Greg Bender - Turn signals as running lights

1157 turn signal mod - BigCee Engineering

Check out this aftermarket turn signal conversion kit from electricalconnection.com:

http://www.electricalconnection.com/other-lighting/tsk-star&sport.htm

Flashing LEDs from Hyperlites should make you more visible:

http://www.hyperlites.com/

Convert Gauge Lights To LEDs

(by Mr. Matchless)

In this guide, Mr. Matchless shows us how to remove the incandescent bulbs from the gauge cluster and replace them with LEDs.

Gauge Illumination Lamps To LEDs

If your gauge cluster has a single turn signal indicator bulb, here is some helpful information from Mr. Steve:

If you have a single [turn signal indicator] bulb in the instrument panel, it is fed by two hot

wires from the turn signals. The indicator bulb acts as a current

limiter and uses the turn signals on the other side as a ground wire.

When the left turn signals are on, the indicator will also light, but

won't pass enough current to light the right-side signals, so it uses

them as a ground. Same thing for the other side.

If you want to use a single LED for your indicator, there is no problem, as long as you use a couple other LEDs to feed it.

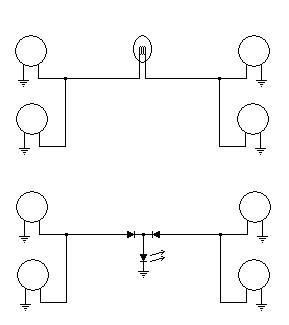

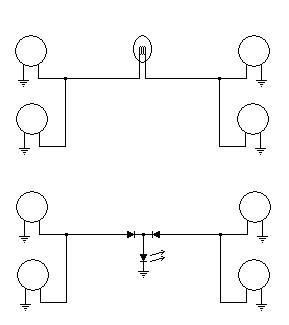

Here is a diagram I did for somebody doing the same thing some time

ago. It only shows the lights, not the wires that come from the

controls, etc., but it shows the original setup with a standard bulb,

then how to wire in two LEDs that will allow the use of a single LED in

the instrument panel.

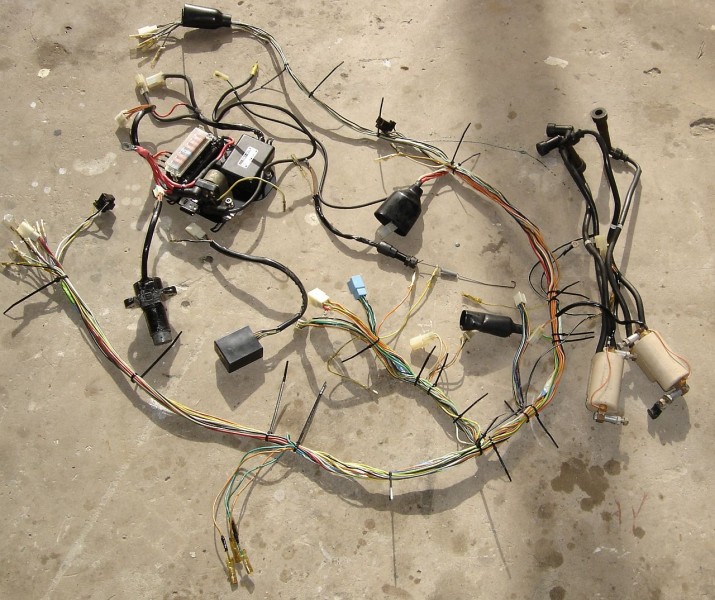

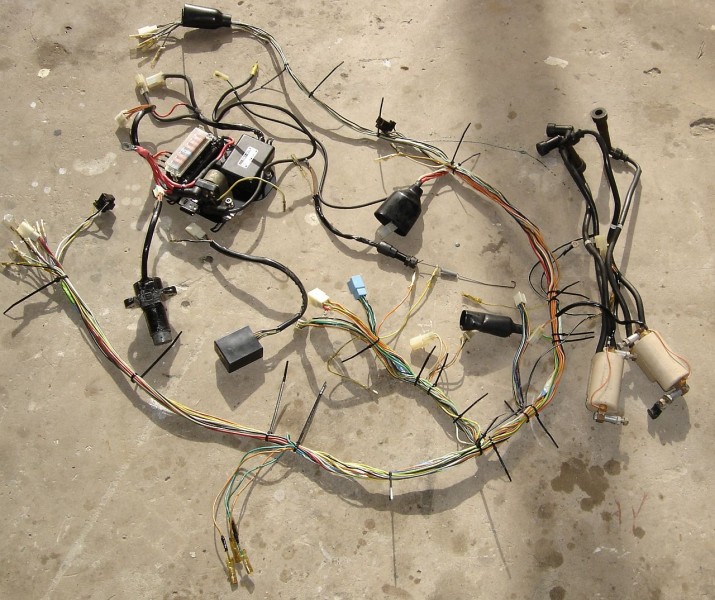

How To Repair Your Wiring Harness

Originally posted by Mr. Joe Guilbeau

Here are some how to tips on repairing the wiring harnesses and how to go about it.

The

connectors that were used on these old GS's were predominately Molex

connectors. Time has improved the technology and I will share a link

with you.

The following source is a pretty cost effective way to

replace those pesky Molex connectors (White, Green and Blue) that tend

to crumble with age.

Use General Motors Delphi division's

WeatherPak connectors, weather-proof with seals. These can be had (for

a bit of a steep price) with the pigtails included. That is, there is a

connector that already has the wire crimped to the the connectors and

seals and these are already seated into the connectors for you. You

will pay extra for this... OR

You could go to this website and pay for the crimping tool, the extraction tool and the separate components.

http://rjminjectiontech.com/?p=12

You

basically slide a seal over the end of the wire that you want to

terminate, then strip off 3/16-inch and then terminate that wire with

the crimp tool, then crimp the seal with that same crimp tool and

insert the Pin/Socket into the proper housing and Pin/Socket position.

This WILL cure the majority of your wiring problems.

These

same connection can be had a a pigtailed pre-assembled package and you

would simply cut your Molex connectors out of the harness and replace

with the respective WeatherPak connector by using bare metal Butt

Splice connectors, crimping into place (after sliding Heatshrink tubing

over the individual wires). After crimping I solder the connection

making sure that the solder is wicked into the Butt Splice Connection,

and then apply some liquid electrical tape to cover all metal exposed

parts, Then heat shrink this extending 1/2-inch out from the ends of

the Butt Splice connector. You are good to go.

Here is a link for the pigtail WeatherPak connectors....

http://www.whiteproducts.net/pigtails.shtml

For a one stop connection there is an eBay outfit that will sell a kit for all you need for one bike:

Ebay Store: HiPo-Parts-Garage_Weatherpack-Electrical-Parts

And the crimp tool:

Ebay Store: HiPo-Parts-Garage/Weather-Pack-Economy-Crimping-Tool-20-14ga

The two links above will suffice for most of anything you might need to fix any problems with wiring harnesses.

Not exactly cheap, but peace of mind is worth something.

(Author's update) Some (legitimate) concerns were raised in this [discussion] and so I thought

that the easiest way to add to the knowledge base was to edit this post

and offer some additiional methodologies for splicing wires together.

Namely Tyco's Soldersleeve

Here is Digikey's Catalog Page...

http://dkc3.digikey.com/PDF/T082/P2121.pdf

No crimping required, simple and straightforward process, clear shrink tubing allows inspection at later dates if desired.

There are many ways to skin a cat, if done properly most any of these

methods will work for you, if done improperly, most of these methods

will fail for you.

I will simply add to this post from time to time to give the dear

reader options that should suffice to get the your particular job done

to your satisifaction level.

For instance, the Soldersleeve's work quite nicely with regards to

integrity and reduced bundle size. By the way, Microtorches work very

well on these kinds of repairs, you can take some of these splices with

you in your tool kit, and be the darling of the techno geeks when some

poor slob has a wiring melt down on the side of the road. Whip out the ultra cool torch, a bit of wire, your handy dandy T-Stripper ( http://www.mytoolstore.com/ideal/ide11-03.html ) and volia!

Cleaning Your Wiring Harness

Originally posted by Mr. Matchless

I

pulled the tape off the wiring loom, removed the two redundant wires

for the third phase charging and cleaned each wire full length with

benzine.

Sprayed out all connectors and bullet connector boots

with brake cleaner. Then dipped contacts in hydrofluoric acid for 5

minutes to clean the brass, dipped in clean water, sprayed with brake

cleaner and finally sprayed with contact cleaner, left overnight and

again cleaned each connector and conector block with brake cleaner. All

connectors are now bright brass and the bullet connector boots look

close to new.

(Optional) Next step is to add new wires for coil and horn relay mod as well as a 12v accessory point and then wrap the loom up.

As the most problems on these old bikes are usually electrical or fuel related I am trying to do this properly.

When you unwrap use "benzine" to clean the old glue and dirt of the plastic wires. It will not harm the plastic.

If

you decide to rewrap use a well known brand of insulation tape, the

cheaper types have the adhesive loosen in hot weather. The types

without adhesive becomes a headache when it unwraps at the ends.

Stay

away from wrapping with "rubber" tape, that usually is the expensive

type with no adhesive and is stretched and bonds into itself. You will

learn new words if you ever have to open the loom sometime in the

future!

If you decide to use the split sprague type conduit for

the wires, just note that it is going to be much wider in diameter at

the head (due to the ridges) and coils area and may cause problems.

Where you have enough space it will look very neat.

Also note

stationary wires are OK in a loose tube, but in areas such as the head

they are pulled and moved and may chafe individually against each

other, when wrapped they bend and move together as one. Wires loose in

a tube may feel better on the steering, but it is not really a good

idea.

If rewrapping the complete loom, pull it out, put it on a

large wooden board and put some nails at the ends and junctions. Take a

few photos.

Unwrap and use cable ties to hold them together at

intervals and at the branches. Clean the wires with a benzine soaked

cloth. Inspect the wires and replace if too short or damaged. Decide if

you are replacing all connectors and connector plugs and have them at

hand. Remove wires such as the 2 stator 3rd phase wires that is not to

be used again. Add you coil, headlight and or horn relay wiring. Relace

any wires with heavier gauge if this is required.

Now make sure

that your wires are clean, straight without any kinks and nicely laying

alongside each other and eleiminate any crossovers. Keep them in place

with a couple of cable ties.

Some

looms have a split sheathing around the wires under the tape to protect

the wires, especially in areas where there is movement. Replace this or

reuse, but fold it over as tightly as possible to keep the diameter

down. Pull the wire tight at each end of the tubing and wrap the wires

for an inch or so and over the tube.

Now start wrapping from the

center moving towards the ends, so as to eliminate any slack and

crossings causing bulges being trapped, At the end overlap the wrapping

a few times and move back a bit so as to not leave an end that can

start peeling back. Always stretch the insulation tape so that it just

starts stretching as you wrap. Try to keep the wires parallel with each

other, crossing over is untidy and makes the bundle thicker. Remove the

cable tie as you get to it.

Finally make sure you have wrapped

the complete loom and the branches as it was done originally. This will

keep out water grime, protect the wires and make the loom look good

again.

Mr. Nessism adds:

Deoxit works well to clean electrical contacts...CLICK HERE for a source and more info.

There are different formulas. I think the D100S version has the strongest cleaning power.

Testing The Ignition System

by Mr. Matchless

Properly localizing a problem with the ignition is sometimes a bit confusing and the following below should of assistance:

- Basic

test, remove spark plugs. Fit them to the plug HT leads and ground them

to the engine. Turn engine with starter and see if plugs spark. If any

one spark plug does not spark swap it out. If the spark seems good on

all 4 plugs, the ignition system is very likely in order. If spark is

not present or very weak proceed with the following tests.

- Remove the tank, left side cover, seat and signal generating unit (pickup) cover at bottom right of engine.

- A good habit is to check the coils and igniter to see if they do

not get very hot once the ignition is switched on, as this will most

likely be the indication of a failed component of faulty connection or

wire.

- If the spark is weak but present, inspect the HT leads and plug

caps. Suspect coil wires and spark plug caps, or voltage at the coils

and thus the battery condition. It could also be due to coils with

partially shorted windings, but do not jump on this cause immediately,

and they may get hot.

- Overheating coils with no spark may also be due to them getting a

permanent full ground either from a faulty igniter or a grounded and

pinched wire. Disconnect the coil plug connectors and proceed with

tests.

- Measure the battery voltage directly across the battery terminals.

If lower than approximately 12.6V first charge battery fully before

proceeding.

- Next measure voltage over the coil connector plug, orange/white

wire and the battery negative terminal. If lower than 12 Volt inspect

the wiring for poor contacts and localise cause of voltage drop.

- Again measure directly across the battery, but pull off the spark

plug leads to prevent engine from firing and swing with starter. While

starter is turning the voltage should stay at least above 11 Volt. Also

swing the starter with the headlights on to see that the voltage does

not drop significantly at the coils while the starter plus headlights

load the battery, which could prove that even if your battery is fully

charged, it cannot give full or sufficient current and is on its way

out or your starter may be drawing excess current (usually unlikely if

starter is spinning at full speed) and pulling the battery down. If it

drops much lower, charge battery fully or have it load tested and

replaced if faulty.

- If all is well up to here you can assume your battery and the positive feed to your coils are in good order.

- With the coil plug connectors disconnected, use an ohm meter and

measure the resistance of both windings on each of the coils. Exact

resistance measurements are not too important, but continuity of the

windings close to the approximate resistance values given indicates

that the coils are in good condition. It must be noted that it is

possible for the coils to only show up a fault when at higher operating

temperatures, but this does not happen frequently.

Ignition coil resistance:

Between the two HT plug caps of the same coil, secondary HT winding, approximately 30 - 35 K ohm

Between the orange/white and white on the first coil and orange/white

and black/yellow on the second coil, primary winding, approximately 2-5

ohm. If this test is within limits you likely have two good coils.

- Locate the igniter and disconnect the plug with the blue and green

wires coming from the signal generator (pickup) at the right bottom of

the engine. Test the resistance across these wires coming from the

signal generator pickup coils, it should be approximately 250 - 360

ohm. If this is in order you have proved the pickups and the wires to

be good.

- The little back box or igniter is now tested as follows. With the

ignition on, kill switch on, test for 12 Volt DC between the

orange/white and the black/white wires in the plug going into the

igniter. This proves that it is getting the correct voltage.

- The next step is to prove whether the igniter is powering your

coils. Remove all 4 spark plugs and connect the HT lead caps to a spark

plug #1, #2, #3 and #4 which is grounded and located to enable you to

see the spark. Ensure all the connector plugs are back in, except the

one with the green and blue wires from the signal generator.

- To simulate the small voltage generated by the pickup coil, prepare

an ordinary 1.5V dry cell with two wires red for positive and black for

negative. Connect the negative black wire from the dry cell to the blue

wire on the connector plug going into the igniter. Switch on the

ignition and kill switch to power the igniter and briefly touch the red

wire from the dry cell positive to the green wire connector going into

the igniter. You should see a spark on plugs #1 and #4 when you touch

the wire and on #2 and #3 when you remove the wire. If this works your

igniter is in a working condition.

- One other check that is often overlooked. Run the bike at night

with all lights off in a dark area and check that no sparks are jumping

from the HT leads to the frame or tank. If so they may need replacing.

- At this stage if all tests have passed you MUST get a spark at all

the plugs when everything is reconnected and the engine is turned with

the starter.

- If a spark that was previously missing has mysteriously appeared,

have a very good look at your wiring and connectors, as something may

be making intermittent contact and corrected itself temporary when you

moved the wires.

- If there is a spark, but the engine will not fire, it could be due

to ignition timing, valve timing or fuel problems. Ignition timing and

valve timing problems are more likely on a bike that has not run yet

after being disassembled and more unlikely to be the cause if the bike

was not taken apart and was running before.

- A quick test with a few drops of fuel directly into the cylinders

before replacing the spark plugs and then trying to start will prove it

to either the fuel system or ignition system.

- If

the engine then starts and runs for a few RPM's the ignition is correct

and you need to look at the fuel and carburettor side.

- If the engine does not fire, but occasionally gives one load pop

through the carburetors or even exhaust, it may be igniting when the

valves are open, the valve timing may be a problem, cam chain or

swapped wires from pickup - plugs firing at wrong time.

- Other reasons could be extremely low compression, too tight valve

clearances, thus not closing fully (usually unlikely on all cylinders

at the same time, but plausible), carburettor faulty or dirty, fuel

line, filter or petcock faulty. Filter can cause an airlock if not

positioned properly to allow free gravity feed.

- Then finally the ignition timing must be set properly. At less than

1500 RPM connect a timing light to #2 or # 3 spark plug and check that

the timing marks line up for 2-3 on F, then move to #1 or #4 spark plug

and check that marks line up for 1-4 on F. Check the advance by pushing

revs up to 2350 RPM and the timing marks should both line up on the 45

mark behind the signal generator mounting plate through the sight hole

at the top. The three mounting screws can be loosened and the mounting

plate can be moved slightly in the elongated holes to meet this.

Points Timing

(by Mr.earlfor)

To

adjust timing with the bike running, you need a dynamic timing light.

To set the static timing (bike is NOT running) all you need is a 12

volt lightbulb and two wires so you can connect it.

Here's the proceedure for

timing the 750. The points are located under the round cover on the

right end of the crankcase/crankshaft.

Setting the points gaps

The round 6" plate that both

sets of points are mounted on (breaker plate) is held in place by three

screws located at 12, 4 and 8 oclock. Loosen the 3 screws on the

breaker plate. Note that the screw at 12 oclock is in a slot. Rotate

the breaker plate until the 12 oclock screw is centered in the slot.

Tighten the three screws.

We will replace the left side set of points first (located at 9 oclock position) These are the points for cylinders 1 and 4.

Take a 19 mm wrench and rotate

crankshaft until points are at widest gap. Unscrew hold down screw on

pointset and remove points. Note the white wire that goes to the

pointset and the placement of the insulator. The insulator must be

correct or the points will be grounded out and will not work. Put the

new points onto the breaker plate, set the gap to 14 thousandths, and

lightly tighten the hold down screw. Install white wire. Rotate

crankshaft once again with 19mm wrench until points are at widest gap.

Check that widest gap remains at 14 thousandths. Adjust and retighten

holddown screw if needed.

Rotate crankshaft until rightside points are at widest gap (for

cylinders 2 and 3) Remove old points and install new points and set gap

at 14 thousandths. Note insulators on black wire installation. Rotate

crankshaft with 19 mm wrench again stopping at widest gap. Recheck gap

as you did with the left pointset. Adjust and retighten hold down screw

on points if needed.

You have just completed setting the points gaps.

Next is the timing:

Timing for cylinders 1 and 4 (the left set of points)

With 19 mm wrench, rotate

crankshaft while looking through the timing window and align the mark

that looks like |F1 with the timing mark on the engine case. (The line

[|] preceeding 'F1' is the mark - |F1.)

Note: Some bikes will have a stationary timing mark on the engine case

and some will have a mark on a stationary timing plate that can be seen

through the timing window.

Connect a continuity light wire lead/clip to the white wire clip on the

left pointset. Clamp continuity light probe tip to ground on the bike

or battery negative terminal.

Turn ignition switch to on. (Do not attempt to start bike, just switch ignition to on.) The continuity light should be on.

Loosen the three screws on the

breaker plate located at 12, 4 and 8 o'clock. Rotate breaker plate

until continuity light just flickers out. Retighten the 12, 4, and 8

oclock screws on the breaker plate.

Unclip continuity lead from left pointset.

Timing for cylinders 2 and 3 (the right set of points)

Rotate

crankshaft with wrench until you see the timing mark F2| becomes

aligned with the stationary timing mark on the engine case. Connect the

continuity light lead to the black wire on right pointset. The ignition

should be switched on and the continuity light should be on.

The

right pointset is mounted to a breaker half plate. You will see that

you can loosen the mounting screws on this breaker half plate and this

will allow you to move the right pointset. This will adjust the timing

without changing the points gap. When you rotated the complete breaker

plate for the left pointset to get the continuity light to flicker out,

thats what you did. You adjusted the timing on cylinders 1 and 4

without changing the gap on their pointset.

Unfortunately,

the whole breaker plate being rotated moves BOTH sets of points, so

that is why you must set the left side first and that is why the right

side is mounted on its own independent half breaker plate.

SOoooooo....

Smile! Loosen the breaker half plate on the right side and rotate as

needed to cause the continuity light to just flicker out. Tighten the

half plate back down when satisfied with the adjustment. Smile!

Remove continuity light and HOPEFULLY, start bike.

Mr. gearman adds:

I

seem to have better luck using an ohmmeter instead of a continuity

light for static timing. I'd also recommend replacing the condenser(s)

and the point am lube felt (if used) while your at it. Here's a little

vid of some points in action: http://s146.photobucket.com/albums/r247/gearman22/tutorial/?action=view¤t=points.flv

Simple Wiring Diagrams for those of you who might be building a new wiring harness for your bike:

http://livetorideridetochurch.blogspot.com/2010/09/i-love-these-types-of-diagrams.html

Right-click and save this diagram:

Here's a diagram drawn up by the GSR electrical guru, Jim (posplayr) for a GS550 but can be adapted for other bikes:

550_Schematic.pdf (about 350kb)

Charging System Health

Mr. posplayr has put together a comprehensive tutorial on keeping your Suzuki GS charging system healthy:

GS Charging System Health (PDF file <1MB)

Quick Test (Procedure by Mr. posplayr)

Sometime people get a little confused in the details of doing the stator

pages and sometimes they forget to check their battery. So just to help

things along if someone is a bit confused and needs a sanity check.

These tests are NOT mandatory as long as you know you have a good battery and can follow your way through the stator pages. Otherwise it is just a nice real quick test.

NOTE: THIS IS NOT TO

REPLACE THE STATOR PAGES. IT IS JUST A QUICK SANITY TEST to see if the

battery is good enough to proceed with the STATOR PAGES. The first part

of the Stator Pages will actually measure how good your connections are

and goes well beyond this QUICK check.

Quick Test Steps:

1.) key off................Normal 12.7 volts-12.9 volts

2.) key on (but not cranking with lights for 10 sec).....Normal 12.2-12.5 volts

3.) at idle (1500 rpm).....12.6volts - 13.2volts

4.) at 2500 rpm 13.5 -14.0 volts

5.) at 5000 rpm.....14.0 -15.0 volts

6.) key off.....slightly higher than measurements # 1 (12.8-13.0 v)

QUICK TEST Diagnosis Summary:

Basically Step #1 and #2 is making sure the battery is charged

and in good health. The drop should be about 0.5 volts for normal

headlamp and coil load (without cranking the starter)

Step #3 is get a baseline starting voltage. This will vary some

depending upon your idle and the particular R/R you have. It could be

lower than the off voltage or as you idle up it will increase to 13.0 v

Step #4 by the time you get to 2500 RPM you should have close to

the maximum output voltage even if you have bad connections. You are not

pushing as much current and this shows that the stator is likely good.

Step #5 by the voltage at 5000 RPM being higher than at 2500 RPM

you have a pretty good indication that your connections are good. If the

voltage at 5000 drops from 2500 you have bad connections. If you

already checked the grounds then it is likely in the positive legs

between R/R(+) and Battery (+) check fuse box and the large bullet

connector to the battery. The voltage climbs above 15.0 V it is likely

the R/R not regulating and is bad bad.

Step #6 If after running for a few seconds in a charging state

the voltage to the battery should have risen a bit. If it is lower than

where you started then you did not charge at all, Again this will vary

some what depending upon how long you let the bike run.

Fuel Gauge Test - A quick troubleshooting guide.

Stay tuned for more odds and ends.

Back to BikeCliff's website.