(Special thanks to Mr. oldryder and Mr. Matchless of the GS Resources Forum)

Have you ever noticed that you don't get a full 12 volts at your ignition coils? This could be due to extra impedence caused by a 20-something year old wiring harness and the fact that there are a few switches and connectors between the battery and the coils (ignition switch, kill switch, etc). Mr. oldryder (Mark) has a simple modification that will ensure 12 volts at the coils and still allow normal operation of all the switches. This should enable a stronger spark, more efficient combustion, increased stamina, cure baldness, and help you lose weight.

Wiredgeorge has an excellent write-up concerning this mod (with a little something extra for you Dyna-S users), CLICK HERE.

Download a PDF file for this mod specifically for our GS Suzuki bikes, with lots of pictures. CLICK HERE.

Here is an excellent write-up by Mr. Matchless explaining several uses for relays on a classic Suzuki GS bike. CLICK HERE to download the PDF file.

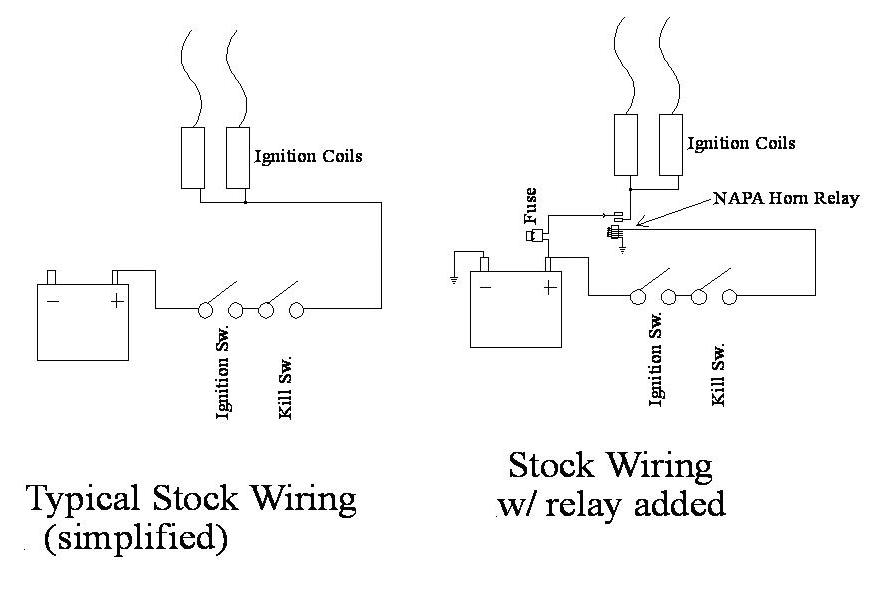

This is a simple (rough) diagram of the modification. To download a PDF version, CLICK HERE.

This is an even simpler diagram.

Mr. oldryder (Mark) offers these instructions:

Please refer to the above diagram(s).

Parts needed before we begin:

Relay ('normally open' type, closes when voltage is applied). A $4 horn relay from NAPA works good. Here's another source.

Fuse holder and fuse (same value as your main fuse)

Misc. extra wire and connectors, just in case.

1.) Locate the main wire supplying voltage to the low (primary) side of the coils.

2.) Disconnect that wire and connect it to one terminal of the solenoid on the relay. Connect the other solenoid terminal to ground.

3.) Have the fuse holder ready. I like the ones that hold a flat blade type fuse but you can use any. Fuse it for the same amperage as the main fuse in the bike's ignition circuit (usually 20 amps).

4.) Connect one terminal of the fuse holder to battery (+).

5.) Carefully route the wire from the (+) terminal to the fuse so you don't someday have a short and burn up your bike.

6.) Connect the other terminal of the fuseholder to one side of the normally open relay contacts.

7.) Connect a wire from the other terminal for the relay contacts to the primary side of the coils.

That's

all. On most bikes it takes about as long to remove the seat and gas tank as it does to add the relay.

I hope this helps.

Mark

______________________________

Here are some editor's notes from Mr. Steve:

You can also get a socket with a protective diode for $1.88. You can get a socket without the diode for $1.75.

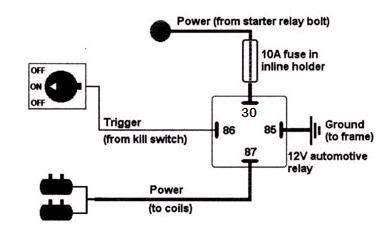

I should give you a bit of a wiring diagram with pin-outs.

If you use the square, Bosch-type relay, terminal 85 or 86 would

connect to the original coil wire, the other terminal (86 or 85) will

connect to ground. Terminal #36 gets connected to the battery (through

the fuse), and terminal 87 goes to the coils.

If you use the socket with 5 wires, the black wire goes to the original

coil wire, the white wire goes to ground. The yellow wire goes to the

battery and fuse, the blue wire goes to the coils.

(If you use the socket with the diode, you are on your own, I have not used that one.)

_________________________________

Here is a diagram (from the KZRiders forum) that goes along with Mr. Steve's clarifications:

Also from the KZRiders forum archives, here are detailed steps :

____________________________________

Ignition coil wiring upgrade

Older

bikes, and KZs and Zs in particular, often exhibit symptoms of rough

running, backfiring through the carbs, and occasionally sooty spark

plugs. When asked about these symptoms, people will often recommend the

use of smaller main jets, dropping the jet needles down one notch, or

tweaking of the pilot (mixture) screw. Carburetor adjustments such as

these are often necessary, especially if the bike has been modified

from stock at all, i.e. aftermarket exhaust, pod filters, etc.

However, if you know that the following conditions are all met, your carbs may have nothing to do with the problem.

* Your air filter is clean, not clogged or dirty.

* You have recently rebuilt your carbs or know that their innards are clean.

*

You know there is no crud in the carburetor float bowls, preferably

because you have installed inline fuel filters that would prevent any

crud from getting into the bowls in the first place.

* Your carburetor float levels are all properly set.

*

The carburetor jetting is approximately correct. A general rule of

thumb is that jets should be increased two sizes from stock for an

aftermarket exhaust, and another 1-2 sizes for pod filters.

To repeat: if these conditions are met, your carbs may not have anything to do with the problem.

Consider

that two things are necessary for complete combustion: the air/fuel

mixture must be correct, and you must have a good spark. Since you've

already determined that your carburetors -- and thus the air/fuel

mixture -- are set up properly, that leaves us with the spark. So now

what?

The problems described can be partially attributed to old

ignition components or improper timing, but even if you have switched

to a state-of-the-art electronic ignition system and new aftermarket

coils, you can still experience these problems.

Why?

It's

fairly common on older bikes, especially with their older wiring and

connections that may have corroded with age, that the current feeding

the coils is insufficient to create a strong spark. If this is the

case, no amount of carburetor tuning will rid you of the problem or its

symptoms. Powering the coils directly from the battery, allowing them

to draw all the current they could possibly use, will eliminate this

problem. Bosch makes a wide variety of standard automotive relays that

will work well for this application, and they can be mounted on the

same bolt that retains the starter relay (provided the bolt is replaced

with a longer one to allow for the depth of the new relay).

Relay connection and installation diagram

To wire this up, you'll need the following:

* 12- and 18-gauge wire

* soldering iron and rosin core solder, intended for electrical (not plumbing) use

* 3/16" heat-shrink tubing (or electrical tape)

* standard automotive relay

* inline fuse holder rated for at least 30 amps

* 10-amp inline fuse (to fit above holder)

* 14-gauge male barrel connector

* 12- and 18-gauge crimp-on female lug connectors

* Wire ties (optional)

DISCONNECT YOUR BATTERY BEFORE PROCEEDING ANY FURTHER!

Instructions for installation:

1.) Crimp a female connector onto one end of a 12-gauge wire and connect this to relay lug #85.

2.)

Heat this wire on its bare end with the soldering iron and allow wolder

to flow through the strands of the wire. This is called "tinning" the

wire. Let it cool for a couple of minutes.

3.) Loosen a frame bolt, wrap the tinned end clockwise around a frame bolt and tighten the bolt down. This is your ground.

4.) Crimp a female connector onto one end of another 12-gauge wire and connect to relay lug #30.

5.)

Put about one inch of heat-shrink tubing onto the other end of the wire

and move it towards the relay and out of the way for now.

6.) Join one end of the inline fuse holder to the end of the 12-gauge wire and solder.

7.)

When the solder joint cools, slide the heat shrink over the solder

joint and carefully hold a match, hair dryer, or other heat source near

it to shrink it down. Alternatively, use electrical tape in place of

the heat-shrink tubing.

8.) On the other end of the fuse holder,

similarly solder a section of wire of a length appropriate to place

under the nut that retains the positive wire from the battery where it

connects to the starter solenoid (starter relay). This will be the

power for the coils.

9.) Tin the end of this wire, place it under the nut, and tighten the nut.

10.) Put the 10-amp fuse into the inline fuse holder.

11.)

Find the positive wire that comes out of your kill switch. It is in a

bundle under the tank and wrapped in a plastic sleeve. You may have to

pull the sleeve back.

12.) Open your right hand switch housing to see

what color the wire that is connected to the kill switch "ON" position

is. This is where you will pick up power to trigger your relay so that

it will power the coils only when the bike is running.

13.) Cut this

wire, strip some insulation from each side of the cut, and splice in a

piece of 18-gauge wire. Cover the splice with heat-shrink tubing or

electrical tape.

14.) Run this 18-gauge wire to the relay, crimp on a female lug connector, and connect to relay lug #86.

15.)

Your coils have positive power leads and ground wires. We don't need to

touch the grounds, which are both black wires or possibly black/yellow

on newer bikes. The positive wires will come together into a

two-into-one connector and be connected to a yellow/red wire which is

the source of your woes! Disconnect the positive coil wires from the

yellow/red wire.

16.) Cap off the yellow/red wire with electrical

tape or heat-shrink tubing and get it out of the way. You won't need it

for anything any more.

17.) Crimp a round male lug-type connector

onto a piece of 12-gauge wire. Plug this connector in where you just

removed the yellow/red wire.

18.) Run the other end to the relay, crimp on a connector, and connect to relay lug #87.

19.)

Wire ties may be used at this point to make the installation neater and

ensure that no stray wires will rub against the valve covers or

cylinder head (which could melt the insulation and short the wire).

Now,

when you start the engine, with the kill switch in the "ON" position,

your coils will be powered by the new circuit we created and your spark

will be much, much stronger. Say goodbye to constantly cleaning your

spark plugs and tinkering with your jetting!

BY George Lesho, edited by Chris Lawson

______________________________________

There you go! I think I'm going to try this mod the next free Saturday I have. A thorough discussion of this mod can be found on the KZRiders forum archives by clicking here. You may view/download a PDF version of the KZRiders diagram and instructions by clicking here.

Thank you for your indulgence,

BassCliff (a.k.a. BikeCliff)

Back to BikeCliff's website